Wuhan City, Hubei Province, China, 4th Jun 2024 – PCBs are the foundational substrates on which electronic product components are mounted, providing support and electrical connections for electronic components. As an essential key interconnect in electronic products, the market potential for the PCB industry is immense. According to the latest data from Prismark, the PCB industry experienced a noticeable rebound in the first quarter of 2024, driven by the recovery in demand from end markets such as consumer electronics and household appliances, as well as the continued strong demand for AI servers and automotive electronics. It is anticipated that the PCB industry will enter a new growth cycle in 2024.

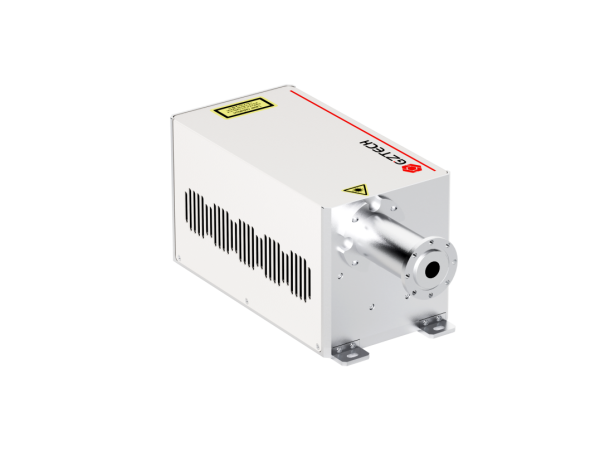

1.GZTECH Solid Nanosecond UV Laser Source Meets PCB Precision Processing Needs

As PCB technology evolves towards multi-layered, high-density, and miniaturized directions, the requirements for manufacturing processes have become increasingly stringent. The precision of PCB processing not only directly affects the reliability of electronic products but also impacts the integrity of signal transmission between various chips. Laser technology, as a representative tool for precision processing, plays a crucial role in PCB processing. Currently, 3W, 5W, 10W, and 15W Solid UV Laser Sources dominate the market. While UV Laser Sources of 20W and above offer improvements in processing efficiency, domestic production of high-power UV Laser Sources at scale is not yet feasible. Most of the market is monopolized by foreign enterprises, with imported high-power UV Laser Sources being expensive and slow in after-sales service, making it difficult for companies to expand reproduction.

GZTECH, with its profound insights into the PCB processing market, has heavily invested in the research and development of Solid UV Laser Sources. Aiming to reduce costs and increase efficiency for PCB manufacturers, GZTECH has launched the industry’s first 40W high-power Solid Nanosecond UV Laser Source, featuring high power and energy, high power and frequency, narrow pulse width, and excellent beam quality, providing outstanding solutions for PCB manufacturing. Additionally, the company offers multiple series of Solid UV Laser Sources with air cooling and water cooling, covering power ranges from 3W to 40W, fully meeting various application needs in PCB manufacturing such as cutting, drilling, and marking.

2.Advantages of GZTECH Solid Nanosecond UV Laser Source

A. High Power

The company’s R&D team, through optical simulations, found the optimal optical solution, adopting semiconductor pumping. The superior pump coupling design combined with multi-stage series gain crystals achieves an electro-optical conversion efficiency of over 10%, with the laser’s average power output exceeding 50W.

B. High Beam Quality

The team, with rich experience in thermal management design, has made special doping in gain crystals to enhance thermal conductivity, effectively reducing thermal effects. This ensures high power output while effectively controlling beam quality. Through iterative optimization of design simulations and practical implementations, the final mode selection achieves fundamental mode TEM00 output, with M²<1.1, and a beam ellipticity of over 90%.

C. High Power Stability

Structural stability is a key factor affecting power stability. The R&D personnel have designed water cooling for each heat-generating point inside the laser, using the optimal cooling solution for high-precision cooling. Additionally, the thermal conductivity of existing conventional gain media is improved, effectively reducing thermal effects. After multiple rounds of thermal simulations and practical tests, the optimal structural design for thermal stability was finalized, ensuring long-term stable operation of the laser. Power fluctuation is only 1.9% over a 12-hour power stability test.

D. Compact Size

The 40W UV Laser adopts an integrated design with built-in beam expansion (optional). Its compact structure reduces the volume by 20% compared to high-power UV Laser Sources on the market, making it easier to integrate.

The actual output power of the 40W high-power nanosecond UV Laser Source launched by GZTECH can exceed 50W, with over 20% power redundancy. It undergoes a full-power burn-in test for up to 7 days before leaving the factory to ensure long-term stable operation.

3.Application Demonstrations

To meet different application needs, GZTECH offers UV Laser Sources ranging from 5W to 40W for various applications such as marking and cutting PCBs of different specifications and thicknesses.

4.GZTECH and Customers Working Together for Mutual Success

GZTECH is committed to serving as an advanced light source supplier for precision manufacturing. In addition to UV Laser Sources, GZTECH has also introduced fiber MOPA, QCW, fiber infrared picosecond, and green laser series industrial laser products. Custom solutions are also available to meet the personalized needs of different niche markets. Furthermore, GZTECH has established sales and sample testing service centers in Shenzhen, Suzhou, and Jinan, China, providing free sample testing services.

Illuminating All Things, Sincere and Far-reaching.

GZTECH is dedicated to continuous technological innovation and product performance enhancement, shaping lasers as foundational tools in future manufacturing. With sincerity and dedication, GZTECH aims to explore broader development prospects together with you, writing a brilliant chapter in the laser industry!

Media Contact

Organization: Wuhan Guangzhi Technology Co., Ltd.

Contact Person: Henry Peng, Overseas Sales Engineer

Website: https://en.gzlasertech.com/

Email: Send Email

Contact Number: +8618627943265

City: Wuhan City

State: Hubei Province

Country: China

Release Id: 04062412846

The post GZTECH Solid UV Laser Source: Boosting Precision Manufacturing in PCB Industry appeared first on King NewsWire. It is provided by a third-party content provider. King Newswire makes no warranties or representations in connection with it.

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No journalist was involved in the writing and production of this article.